We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Modern Doors FAQ

Frequently Asked Questions:

- What common methods of door construction are there? How is the door made?

- What colours and finishes are available?

- What is a wood veneer?

- What types of glass are available in doors?

- What door sizes are available in the UK? How to measure a door? What should I allow for when measuring a door?

- What is the guarantee on the doors and what does it cover?

- What are the current Building Regulation requirements for energy efficiency of front doors? What U-Values do I need?

- How much can I trim off the door? What is the adjustment allowance?

- What is a Fire Door? What does FD30 stand for? Do I need a Fire Door?

- What is FSC (Forest Stewardship Council) certification? How do I benefit from it?

- What is a door frame? Do I need it?

- What is a weather bar? Do I need it?

- What types of ironmongery/door hardware are there and what are they made of?

- What is a backset? Can you explain the dimensions given on ironmongery (door hardware)?

- What are the bolted through and face fitted methods of fitting ironmongery (door hardware)?

- What is Secured by Design scheme? How do I benefit from it?

- What is the product availability?

1. What common methods of door construction are there? How is the door made?

A. Materials - engineered timber components

In the past doors were made solely from solid timber, however with the invention of engineered timber products such as particle boards, fibre boards and veneers the method of constructing doors has evolved. Nowadays almost all mass produced internal and external timber doors are made using a combination of man made, engineered products (chipboard, MDF, veneer, laminated timber and others) and adhesives. This method has several advantages:

- sustainability and eco aspect - using engineered products reduces timber waste as sawmill scraps and other wood waste can be used for production.

- low cost - more efficient use of timber logs allows to produce more doors from a single batch of lumber than traditional methods. Also timber species previously seen as unsuitable due to aesthetical reasons can be utilised to produce engineered components.

- greater stability - man made engineered timber products are designed to maximise the natural stength and stiffness of wood and most of engineered products offers greater stability and structural strength than solid timber, with some being stronger than steel.

- versatility - more design, size and performance options available due to a large variety of engineered products. Most of contemporary style doors cannot be made using solid timber because of its limitations.

Although solid timber doors are still being produced, usually as bespoke, made to order doors (we often produce bespoke external door sets for non standard openings from solid timber), their cost can easily double or triple the cost of equivalent engineered doors and many will see it as unnecessery expense while others will prefer the feel and weight of a solid timber door.

For further reading about engineered timber products, visit Wikipedia/Engineered Wood

B. Joints

Door elements are still jointed using 2 traditional types of joints - Mortice & Tennon and Dowelled, although there are many variations of them currently in use.

- Dowelled – Commonly used in carcasses and frames, although it is not the strongest type of timber joint. Dowel joint uses small piece (pieces) of timber fitted into holes in both pieces of timber. It relies heavily on glue.

- Mortise and Tenon – Simple and strong, this type of joint has been used for thousands of years. One piece of timber is narrowed at the end and fits into a hole in the second piece of timber. The joint is then glued or wedged with small pieces of timber to lock it in place.

C. Design types

From a design perspective, these are currently 3 of the most common types of doors available:

back to the top

- Panel (or Panelled) doors – Also called stile and rail doors, are built with frame and panel (or glass) construction. It’s a basic construction of vertical and horizontal stiles and rails filled with wooden or glass panels. Stiles and rails are jointed using either Dowelled or Mortise and Tenon joints.

- Moulded doors – Similar to panel doors, moulded doors are built with frame and jointed boards. Similarly all sections are joined using either Dowelled or Mortise and Tenon joints.

- Flush doors – Very popular recently due to design versatility and great performance. Flush doors are built using solid chipboard (particle) core, framed around with solid wood stiles and rails and over veneered. They are usually heavier than panel or moulded doors and provide better thermal and sound insulation. Also, because of their (usually) completely flat surface they are much easier to keep clean.

2. What colours and finishes are available?

A. Colours

Currently the most popular timber species used in the production of doors are oak, walnut, hardwood and pine. There are a wide variety of doors readily available from these species in standard sizes and in a range of contemporary or traditional designs. Additionally, species like maple, wenge or ash and also modern man made veneers such as grey ash or chocolate grey can be found across our range. As well as this we offer bespoke doors in virtually any timber veneer, whether natural or man made, as well as with laminated surfaces or painted/stained to the colour of choice. Examples of bespoke internal doors can be seen here: Bespoke Internal Doors

B. Finishes

Ready made standard doors are available in one of four finishes:

- Unfinished - Completely untreated door, ideal for on-site finishing, especially for custom colour matching (staining) with flooring or furniture. Unfinished doors need to be treated prior to installation and accordingly to manufacturers instructions, attached to every door.

- Factory prefinished (clear lacquered) - Several coats of factory applied A/C lacquer, giving a smooth clear finish and adequate protection to internal doors. Prefinished doors are delivered ready for installation.

- White primed - Several coats of factory applied white primer, ready for finishing coat. Ideal for on site finishing, especially for custom colour matching (painting).

- Fully painted - Fully finished door with coats of primer, paint and A/C lacquer for protection. Smooth, sprayed finish with maximum protection, delivered ready for installation.

Bespoke doors are available in an unlimited choice of finishes with custom sheen levels, including high gloss. Comprehesive colour matching service also available.

3. What is a wood veneer?

Wood veneer is a thin slice of solid timber. Veneering is often thought of as a cheaper alternative to well finished solid timber, however for structural reasons, many of the most beautiful timbers are not suitable for use in solid form. Even well seasoned timber is subject to shrinkage, casting, twisting and splitting, especially in central heated homes; and many solid timbers have an irregular microstructure which, in shaped work, can shorten the grain and reduce their strength. Furthermore, even if these timbers display none of the above faults, they along with the more common hardwood species would be rapidly depleted.

Carefully selected and applied to the right base or groundwork, veneers not only reduce the cost of materials but also enlarge the scope of the designer to create beautiful patterns, much of which could not be made from solid timber. Small areas of rare hardwoods or common burrs can be cut and built up to cover large areas. Timbers can be cut in such a way that, when used as veneers, they appear as beautiful mirrored repeat patterns or many other decorative effects.

Veneers are basically thin slices of wood. Traditionally they were sawn, but now they are always sliced with large, powered knives. Sawn veneers vary in thickness from 1.5mm to 6mm, the most common being 3mm. Modern veneers tend to be fairly standard at 0.8mm, but they can be very much thinner (0.3mm) or up to 9.5mm thick. The thickness depends on the type of timber rather than the method of cutting.

Several methods are used to create various grain patterns. The most commonly produced patterns are:

- Crown - Veneer cut from this part of the log produce leaves with crown pattern with some straight grain either side. As the crown cut moves through the log towards the centre, the leaves become wider with the crown being narrower and better defined, with wider straight grain sections on either side

- Quarter - Leaves cut in this method produce fairly straight (parallel growth rings) grain patterns

- Rotary - Veneer cut in a continous roll, producing wide grain pattern

However, there are other types of veneer appearances:

- Birdseye - Figure in veneer exhibiting numerous rounded areas resembling small eyes

- Quilt - Blistered appearance shimmering scalloped pattern

- Pommele - A scalloped figure, most usually found in mahogany

- Burl/Burr - Abnormal growth producing tightly packed buds and knots producing highly decorative veneer that mostly appear as rings and dots

- Figured - The markings, often forming wavy shimmering patterns, these may be regular or irregular ranging from fiddle back to block figure

- Flame - Otherwise known as curl or crotches. This veneer is from the fork in a tree and the pattern resembles a flame

Reconstructed (man made) veneers - Reconstructed Veneers are sliced from a laminated timber block made from various wood species, dyed throughout and glued together under pressure in parallel configuration. One of the perceived benefits of reconstructed veneers is the consistency in colour and grain of the veneer. Within block lots, there is generally acceptable consistency of colour, with some subtle grain differences. Due to batch dyeing, there can be small colour variance from block to block.

4. What types of glass are available in doors?

The updated British Standard "BS 6262: Part 4: 1994 Code of Practice for Glazing for Buildings", introduced new requirements that glazing fitted in 'critical locations' in domestic buildings must be safe. This may be achieved for example by fitting safety glass, small panes of ordinary glass, thicker ordinary glass etc. Certain internal and external areas are considered 'critical locations' in terms of the safety of vertical glazing, as they are at risk from accidental human impact.

The critical locations defined by the standard are similar to the Approved Document N of the Building Regulations 1991. Domestically for doors and side panels any glazing or part of that glazing, which is between the finished floor level and a height of 1500mm above the floor level, is in a 'critical location'.

Most common types of safety and fire rated glass used in doors:

- Laminated glass (usually 6,4mm thick) - Consists of two or more sheets of ordinary glass which are attached together by a plastic interlayer. The interlayer keeps the layers of glass bonded even when broken, and its high strength prevents the glass from breaking up into large sharp pieces, it also gives the glass a much higher sound insulation rating, due to the damping effect, and blocks 99% of transmitted UV light. The interlayer can be either clear (for transparent glass) or white (for obscured glass)

- Wired glass (6mm) - This glass has a mesh of wires embedded in it. Certain types of wired glass can satisfy the impact requirements for safety glass while giving a level of fire resistance. It provides up to 60min of fire resistance

- Toughened glass (4-25mm thick) - This looks like ordinary glass but receives a special heat treatment process to toughen it. It is much stronger than ordinary glass and on impact disintegrates into small granular pieces, which are not sharp, reducing the risk of injury. Commonly used in double glazed units, can be sandblasted for obscurity or special patterns

- Double glazed units (12-32mm thick) – 2 pieces of glass (usually Low E) sealed together with air or gas in between them. To comply with safety regulations for doors (see above), glass used in double glazed units must be toughened or laminated

For further reading about types of glass and their benefits, visit Glass&GlazingFederation/Technical

5. What door sizes are available in the UK? How to measure a door? What should I allow for when measuring a door?

A. Ready made door sizes available in the UK, with conversion to inches and feet (where applicable):

Single Internal Doors

UK Imperial Sizes

mm inches feet

381x1981mm 15"x78" 1'3"x6'6"

457x1981mm 18"x78" 1'6"x6'6"

533x1981mm 21"x78" 1'9"x6'6"

610x1981mm 24"x78" 2'0"x6'6"

686x1981mm 27"x78" 2'3"x6'6"

711x1981mm 28"x78" 2'4"x6'6"

762x1981mm 30"x78" 2'6"x6'6"

813x2032mm 32"x80" 2'8"x6'8"

838x1981mm 33"x78" 2'9"x6'6"

864x1981mm 34"x78" 2'10"x6'6"

914x1981mm 36"x78" 3'0"x6'6"

UK Metric Sizes (milimeters only)

326x2040mm

426x2040mm

526x2040mm

626x2040mm

726x2040mm

826x2040mm

926x2040mm

Internal Double Doors

mm inches feet

915x1981mm 36"x78" 3'0"x6'6"

1067x1981mm 42"x78" 3'6"x6'6"

1168x1981mm 46"x78" 3'10"x6'6"

1220x1981mm 48"x78" 4'0"x6'6"

1372x1981mm 54"x78" 4'6"x6'6"

1524x1981mm 60"x78" 5'0"x6'6"

External Single Doors

mm inches feet

762x1981mm 30"x78" 2'6"x6'6"

813x2032mm 32"x80" 2'8"x6'8"

838x1981mm 33"x78" 2'9"x6'6"

864x2082mm 34"x82" 2'10"x6'10"

915x2134mm 36"x84" 3'0"x7'0"

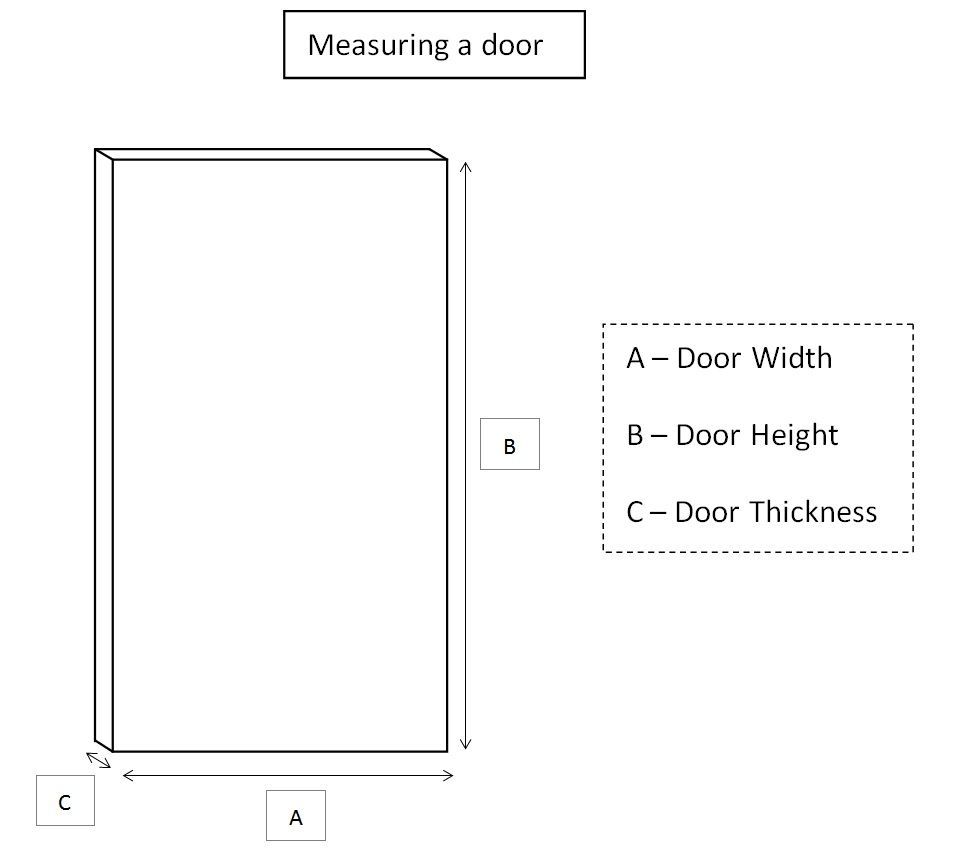

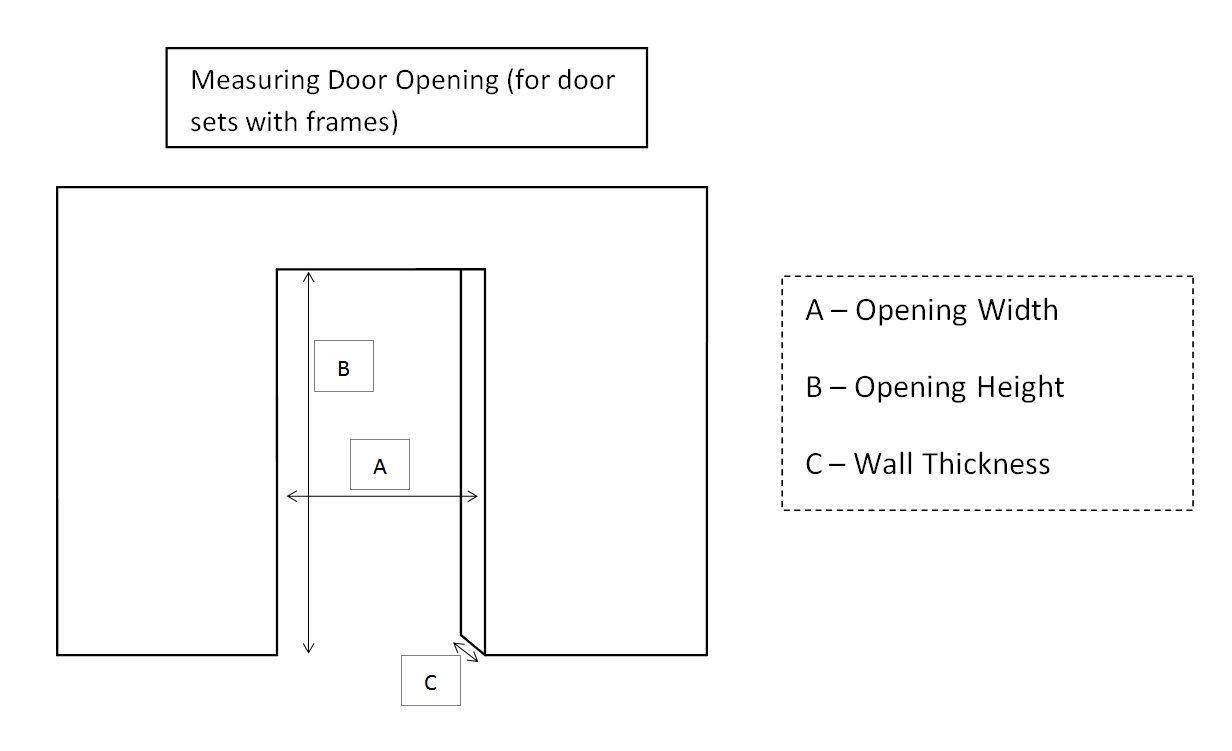

B. Diagrams below show how to measure a door only or how to measure a door opening for a door set (door and frame)

C. When providing us with door opening sizes, as per the diagram above, we will calculate the gaps needed and the correct door size, however, if you wish to make the calculations yourself you must allow for appropriate the gaps around the door for it to operate correctly. The door needs a 2-3mm gap between itself and the frame at the sides and the top, it also needs a 3-5mm gap between itself and a finished floor level. You also need to allow for 5-10mm gaps between the frame and the walls (sides and top), especially when calculating measurements for new openings (new builds), this space is usually filled with building foam and covered with architraves after installation. If in doubt, please contact us and we will provide assistance.

6. What is the guarantee on the doors and what does it cover?

Each door comes with its own manufacturer's guarantee attached to the door, as well as storing, handling, finishing and installation instructions. Please refer to these documents for more details.

In general the majority of our doors are supplied with a 10 year manufacturers guarantee, which covers all types of manufacturing defects, visible and hidden. All doors however are subject to appropriate storing, handling, finishing, use and installation. The guarantee does not cover damages and faults developed through inapropriate storing, handling, finishing, use or installation. Natural timber occurences such as colour or grain variation, spots, knots are not considered as faults.

Ironmongery products usually carry a 10 or 25 year manufacturers mechanical guarantee, which covers the mechanical parts and its operation. Certain door hardware such as handles carry also a separate guarantee for finish, usually 3-5 years (please enquire about a particular product for more information on its guarantee).

7. What are the current Building Regulation requirements for energy efficiency of front doors? What U-Values do I need?

The current information provided in Building Regulations Documents L1A (New Dwellings) 2010 & L1B (Existing Dwellings) 2010, state:

| Fitting | Standard for new fittings in new dwellings | Standard for replacement fittings in an existing dwelling | Standard for new fittings to an extension in an existing dwelling |

| Doors with greater than 50% of their internal face area glazed | 2.0W/m2K | 1.8W/m2K (or exempt if fitted into existing door frame) | 1.8W/m2K (or exempt if fitted into existing door frame) |

| Other doors | 1.8W/m2K | 1.8W/m2K (or exempt if fitted into existing door frame) | 1.8W/m2K (or exempt if fitted into existing door frame) |

We clarify the subject of u-values for external doors in a series of articles in our Blog/Uvalues

For further information about u-values and building regulations, refer to PlanningPortal/Regulations

8. How much can I trim off the door? What is the adjustment allowance?

This depends on the specific door and is described in the instruction manuals supplied with the door, please refer to that document before trimming. As an indication:

- all internal doors produced by XL Joinery can be trimmed by up to 6mm on any given side, top and bottom - so up to 12mm overall on the width and/or the height

- all external doors produced by XL Joinery can be trimmed by up to 10mm on any given side, top and bottom - so up to 20mm overall on the width and/or the height

- all doors (internal and external) produced by LPD can be trimmed by up to 3mm on any given side, top and bottom - so up to 6mm overall on the width and/or the height

All trimmed edges must be fully sealed (finished) to comply with the manufacturers guarantee requirements and to prevent doors from being damaged.

Trimming more than the allowed amounts voids the guarantee and is generally not recommended as it carries a risk of exposing the door core to moisture, which usually results in permament damage. Instead we can offer our quality bespoke door service, which allows us to produce doors in the exact required dimensions, avoiding any trimming whatsoever.

9. What is a Fire Door? What does FD30 stand for? Do I need a Fire Door?

A Fire Door is a heavier and thicker door, used to prevent the spread of fire and allow safe escape from a building in the event of fire. Fire Doors are tested in laboratories and rated for their fire resistance:

- 44mm thick FD30 Fire Doors - the most common Fire Doors, offering 30 minutes of fire protection. Widely used as internal doors in domestic applications and apartment entry doors in multi-residential buildings

- 54mm thick FD60 Fire Doors - usually bespoke, made to order doors offering 60 minutes of fire protection. Used in shools, hospitals and other public buildings

- other - FD90/FD120/FD240 - rare Fire Doors produced for special applications, where the risk of fire is greatly increased, such as petroleum and heavy industry buildings. With an increased thickness 64mm and more they offer 90, 120 or 240 minutes of fire protection

For a Fire Door to fully comply with Fire Regulations it needs to be installed in an appropriate frame set, including fire (intumescent) seals which expand when exposed to heat, sealing the door set and preventing the spread of fire. All other components of the door set, such as the door hardware - hinges, handles, locks, door closers etc. must also comply with the requirements of Fire Regulations for the door set to be considered Fire Resistant.

Sometimes there is an additional requirement for the door set to also prevent the spread of smoke, usually described as FD30S or FD60S. In this instance, a combined fire and smoke seal must be used to meet this requirement.

Usually the majority of the internal doors in 3 story buildings, buildings with converted lofts and house extensions, as well as apartment doors are required to be at least FD30 fire resistant. To check whether your property requires fire doors please contact your Council or Building Inspector.

We further investigate the subject of fire doors in a series of articles in our blog - Blog/FireDoors

You can also refer to FireSafetyAdviceCentre

10. What is FSC (Forest Stewardship Council) certification? How do I benefit from it?

Forest Stewardship Council is an international non-profit organisation promoting responsible management of the world's forests, established as a response to illegal exploitation of forests and global deforestation for commercial reasons. Their global certification system for forests and forest products ensures sustainability and biodiversity of forests, maintains economical well-being of local communities and promotes restoration and conservation of natural forests.

There are 3 types of certification provided by the Forest Stewardship Council:

- Forest Management Certification - confirms forests full compliance with FSC Principles and Criteria

- Chain of Custody - allows tracking of product materials back to the forest it originated from

- Controlled Wood Certification or FSC Mix label - allows mixing certified and uncertified materials in a controlled environment. This prevents the use of illegally harvested wood or wood harvested in areas where genetically modified trees are planted.

The majority of our timber doors are FSC certified and the range is constantly increasing. We are also able to offer a Chain of Custody certificate on our bespoke doors which means the timber used in its production can be traced back to the forest and a particular tree log if needed.

We strongly believe that the FSC initiative benefits everyone from forest workers to end user, and most importantly it benefits the environment at the same time providing economically sustainable supply of timber for our beautiful wooden doors.

For further reading about the FSC initiative, please refer to: FSC

11. What is a door frame? Do I need it?

A door frame is a casing installed in and around a doorway which allows for a door to be installed. Door frames as well as the doors are absolutely essential components of any door set.

You don't need to change the frame with the door if the existing frame is in good condition and you are changing for a like for like door (same size and thickness).

Internal door frames are usually made of flat door linings with planted on door stops. Architraves are often included as part of a frame set as they cover the gap between the door lining and the wall which is necessary in case of imperfections in the wall (structural opening). External door frames are usually thicker with the door stop and lining being combined in a single piece of timber to prevent water leaks and improve security.

We offer all external doors with optional matching frames produced by the same factory as the door to ensure compatibility and front door sets with side panels are sold complete with matching frame sets too. We also offer frame packs for internal doors - single and double, as well as matching architraves and skirting boards - InternalFrames

How to measure a frame size/opening size

12. What is a weather bar? Do I need it?

A weather bar is a timber water drip bar installed at the bottom of external doors. It prevents water from leaking under the door by deflecting it away from the face of the door.

All our oak external doors are offered with optional matching weather bar and we recommend to always install a weather bar on external doors.

The image below, shows an oak weather bar installed at the bottom of an oak external door in a showroom setting.

13. What types of ironmongery/door hardware are there and what are they made of?

All kinds of metal door furniture whether exposed, such as handles, knobs, letterboxes etc. or concealed such as hinges, door closers, locks etc., are considered to be door hardware or in other words ironmongery. Iromongery is generally made of metal, although certain parts can be made of rubber or plastic. There is a number of commonly used metals as base materials for door hardware, depending on application and performance requirement it can be - zinc, aluminium, brass, stainless steel and some times with addition of strenghteners such as magnesium. On top of base material, an appropriate finish is applied with the most common being polished chrome, satin chrome, polished brass, satin nickel, satin stainless steel and bright stainless steel for exposed parts and anodised or painted finish on concealed parts.

14. What is a backset? Can you explain the dimensions given on ironmongery (door hardware)?

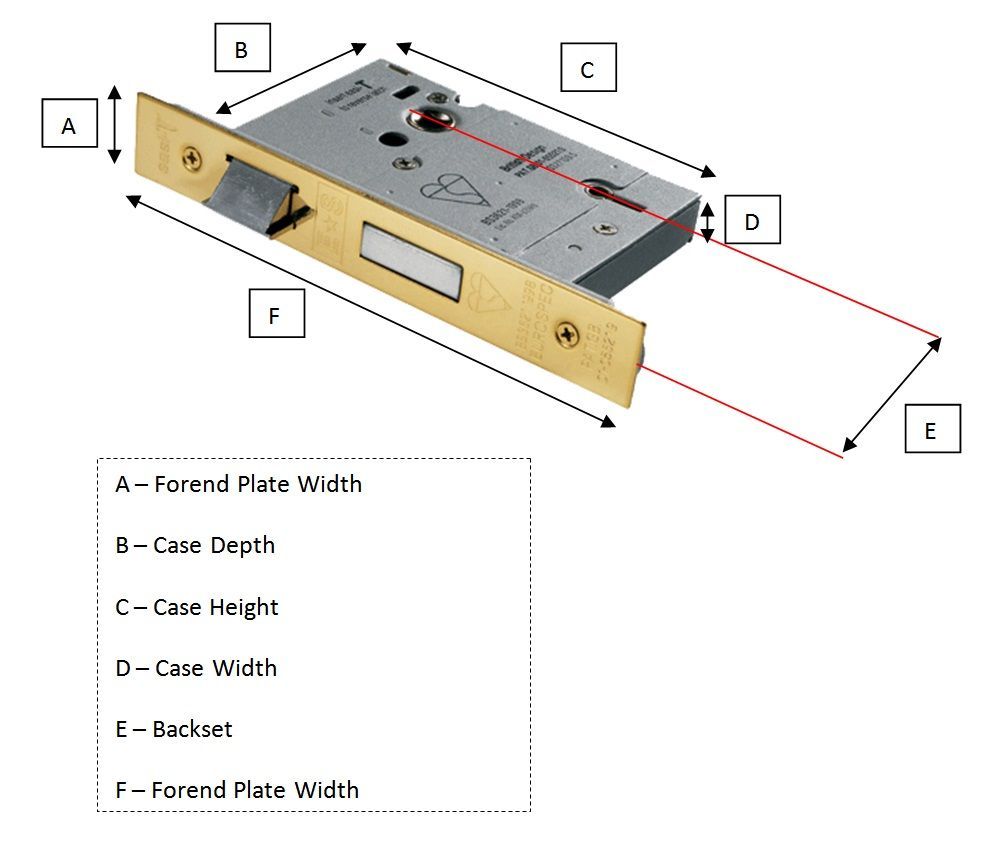

Backset is the distance between the edge of the door and the centre of the handle's spindle or key hole, or in other words how far is the handle set back from the edge of the door. The diagram below shows the backset (E) and other commonly used dimensions related to locks and latches:

15. What are the bolted through and face fitted methods of fitting ironmongery (door hardware)?

There are generally 3 methods of installing ironmongery (door hardware) on timber doors:

- Morticed ironmongery - the majority of locks, latches, hinges and drop down seals are morticed (recessed into the edge of a door) leaving only a small area visible to the eye. Routers and/or chisels are used to cut out these openings

- Bolted through ironmongery - Certain door hardware such as pull handles, letterboxes, pull knobs and some lever handles and escutcheons must be bolted through for secure fixing. This means the fixing bolts go through the door and are tightened on the other side of the door. Usually this method is used where there is a need for increased security as it prevents disassembling of door hardware from outside (for example this applies to security escutcheons) or to strenghten the fixing where a use of force is necessery for door operation (for example with long external pull handles or door knobs)

- Face fitted ironmongery - the majority of lever handles, escutcheons, thumbturns, door numbers, letters and many more fall into this category. It's a simple plant on and secure with screws method and does not require any other tools other than a screwdriver

Please always refer to the installation instructions attached to the product before installation as incorrect product installation will result in a loss of a gurantee and may damage a door.

16. What is Secured by Design scheme? How do I benefit from it?

Secured by Design is a police initiative to encourage the building industry to adopt crime prevention measures in the design of products and developments to assist in reducing the opportunity for crime and the fear of crime. The company Secured by Design is owned by the Association of Chief Police Officers and operates a licensing scheme for the use of Secured by Design logo and term "Police Preferred Specification" on products which have passed the required tests.

Research has shown that developments using Secured by Design products and materials are half as likely to be burgled and show a reduction of 25% in criminal damage.

Modern Doors actively promotes products accredited by Secured by Design scheme, offering a selection of accredited locks and hinges, as well as promoting bespoke front doors designed to conform with and accredited by Secured by Design scheme.

For further reading, please visit OfficialSBDWebsite

17. What is the product availability?

Ready made (stock) Items - usually 4-6 working days from orders placed, subject to stock availability.

Bespoke items - usually within 4 weeks from orders placed.

Ironmongery (door hardware) - usually next working day, from orders placed.

Please bear in mind that in certain unforseeable circumstances minor delays may occur, this includes but is not limited to adverse weather conditions, accidents, breakdowns and similar occurences. In such circumstances we treat all affected orders as top priority and aim to deliver the goods as soon as it is physically possible.

100% secure shopping

100% secure shopping  30 days money

30 days money  5 star rating on

5 star rating on  10 year guarantee

10 year guarantee  UK delivery

UK delivery