Door hardware otherwise known as ironmongery, is more than just handles and knobs, especially when looking at external doors. Apart from the aesthetics, the most important factors are security and durability, other desired factors are functionality and weather resistance. Let’s look closer at the types of ironmongery being used and examples of available products, starting with door hinges.

Door Hinges

Unless it’s a pivot door, every external door must have hinges installed to swing open and close. There are literally hundreds of types of hinges available in the market. How to find the right one?

First of all, external doors require minimum 3 hinges per door leaf – there is a requirement for all escape route doors to have a minimum of 3 hinges. Also, external doors are usually heavy and actually require 3 hinges to take the weight, but on larger, heavier, thicker doors it may even require 4 hinges per leaf, it all depends on the quality of hinge and its maximum load against the weight of the door. On top of that, we should always allow for extra weight for unforeseen circumstances like external forces, uneven wear, additional ironmongery such as door closers (use of door closers can add even up to 75% to the calculated door mass) etc. and it all becomes rather confusing and difficult to calculate, so let’s simplify –

Rule 1: use 3 good quality hinges per door leaf unless it’s an oversized door

(54mm thick or more, 1100mm wide or more, 2400mm high or more), in which case it’s best to get a door or hardware specialist to calculate if 3 hinges are enough or 4 are needed.

One of the most important factors is the material the hinges are made of. Cheaper hinges are usually made of brass with a polished chrome or satin chrome coating – these should not be used on external doors as they are prone to corrosion and could snap under a heavy load. On exterior doors, only solid stainless steel hinges should be used and stainless steel as a material comes in a variety of grades based on a number of physical properties like density, corrosion resistance, thermal expansion etc. The most common grades of stainless steel used for hinges in the UK are grade 304 and grade 316.

Hinges however are also graded based on several different factors according to BS EN 1935:2002, such as security, durability, category of use etc. The most commonly used within the industry is simply Hinge Grade varying between 1-14, see table below:

Hinge Grade

| Hinge Grade | Usage | Test Cycles | Door Mass |

| 1 | Window | 10,000 | 10kg |

| 2 | Window | 10,000 | 20kg |

| 3 | Window/Door | 25,000 | 20kg |

| 4 | Door | 200,000 | 20kg |

| 5 | Window | 10,000 | 40kg |

| 6 | Window/Door | 25,000 | 40kg |

| 7 | Door | 200,000 | 40kg |

| 8 | Window | 10,000 | 60kg |

| 9 | Door | 200,000 | 60kg |

| 10 | Door | 200,000 | 60kg |

| 11 | Door | 200,000 | 80kg |

| 12 | Door | 200,000 | 100kg |

| 13 | Door | 200,000 | 120kg |

| 14 | Door | 200,000 | 160kg |

To confuse the matter even further, hinges come in different sizes and thicknesses (2mm, 2.5mm, 3mm, 4mm) which means a smaller, thinner hinge made of higher grade of steel could be just as strong as a bigger, thicker hinge in a lower grade of steel. This is where the hinge grading helps comparing the actual strength of hinges. In the UK the most popular grade of hinges for external doors is grade 13, which we recommend as a default hinge grade. To conclude –

Rule 2: for external doors use hinges minimum of grade 9 and grade 13 is recommended.

Hinge Mechanism

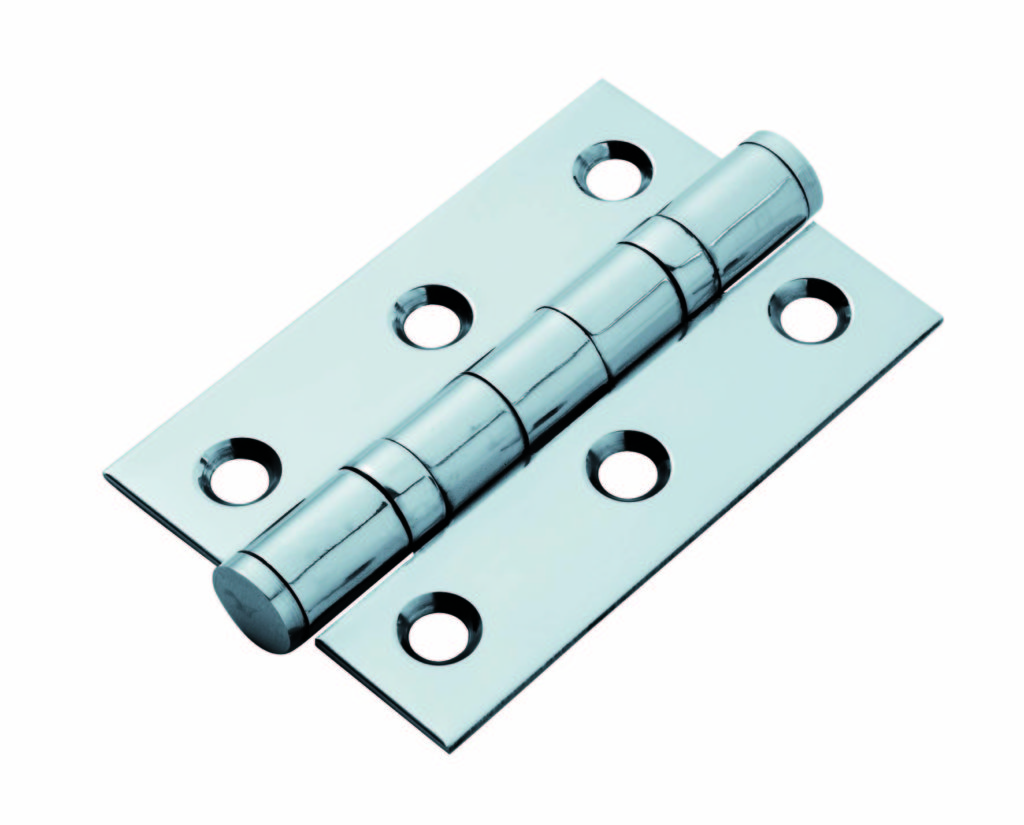

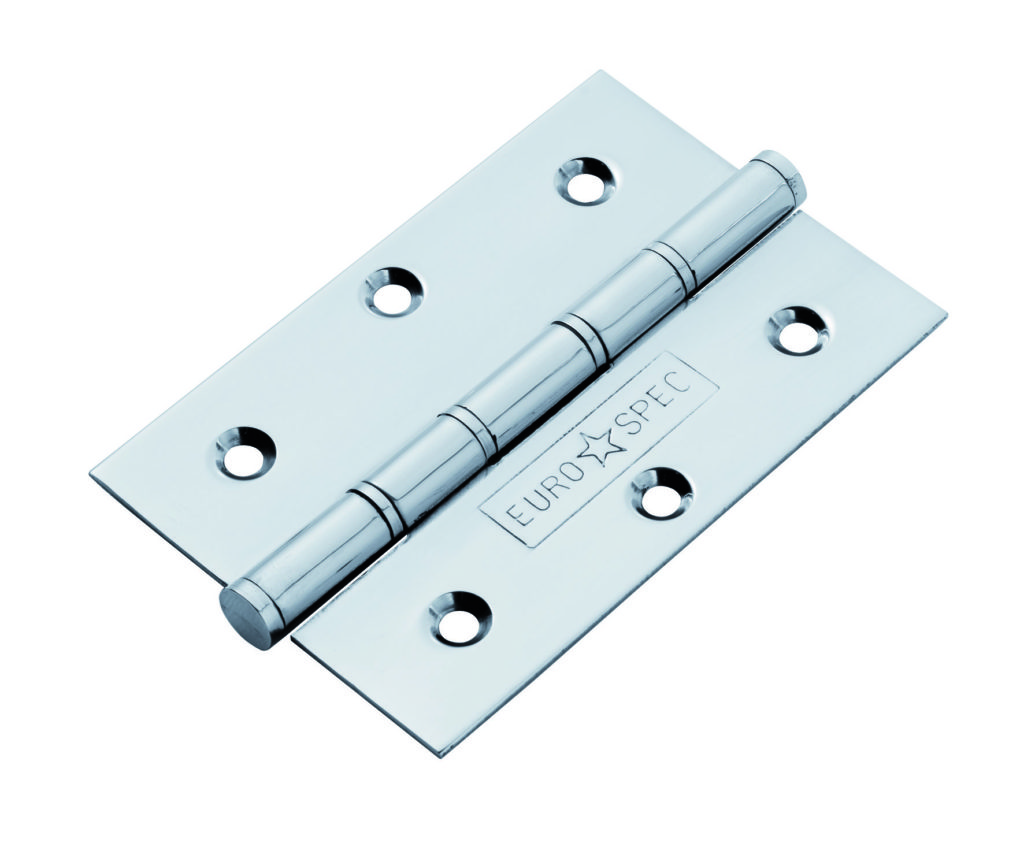

Apart from unusual circumstances the only 2 types of hinges to consider are butt hinges and concealed hinges. Butt hinges have 2 identical halves connected by a round knuckle making a rotary movement. It looks and works a little bit a like a butterfly. Butt hinges have a variety of sub types each having some subtle differences, the most common are:

- washered hinges – Thinner knuckle with movement made on metal washers. Not recommended for external applications.

- ball bearing hinges – thicker knuckle with ball bearing mechanism. Recommended inexpensive, high durability and low maintenance hinge.

- thrust bearing hinges – thicker knuckle with thrust bearing mechanism. High end butt hinge suitable for very heavy loads, highest durability, no maintenance but significantly higher cost.

Apart from butt hinges there are also concealed hinges, which are becoming very popular nowadays. They are completely invisible from either side of the door, as they are recessed into the frame and the door. This is of course desired from an aesthetics point of view but there are certain disadvantages to bear in mind:

- Concealed hinges require specific custom-made frames (non-rebated). The most common in the UK rebated external door frames will not work.

- Concealed hinges require recessing deep into the frame and the door.

- Most are not suitable for high traffic areas and their maximum load is lower than in butt hinges.

- They are the most expensive hinges for external doors.

Rule 3 – use ball bearing butt hinges as default for most domestic and commercial scenarios, alternatively concealed hinges or thrust bearing hinges for more specific requirements.

Door hinges & Security

The majority of external doors in the UK are opening inwards. This requires hinges (or the knuckle) to be positioned inside the building behind a rebated frame, which means the hinges are protected from tampering from outside. The only way to break through the hinges is by forced entry. Outward opening doors have hinges accessible from the outside which makes them an easy target for tampering. Concealed hinges are not accessible from either side which makes them the most secure, however their high cost and the need for a special frame may be an obstacle and for the majority it will not be necessary. There are also ball bearing butt hinges with special, hidden security studs preventing forced entry. It’s a combination of a hinge and a door bolt, where both leaves of a hinge, lock together – see picture below. This prevents doors from being lifted out and even doors opening outwards cannot be attacked from outside. With a minimum of 3 hinges required per door, they provide 3 extra locking points on the hinged edge. These hinges are inexpensive with cost around 15-20% higher compared to a regular ball bearing butt hinge and we highly recommended them.

Conclusion

Taking everything into account, we can conclude that, for the overwhelming majority of external door scenarios in the UK, using 3no grade 13 ball bearing security butt hinges will be more than sufficient and inexpensive at the same time. The total cost of these, at the time of writing, is approx. £17 per door leaf (please note, hinges are sold as pairs, so 4 hinges must be purchased with the cost being approx. £22). As an added bonus, these hinges come with 25 years mechanical guarantee and are CE tested for quality.

For abnormal sizes, weight, any non-standard situation or if you need concealed hinges, you should ask your door supplier for a specific advice. At Modern Doors we supply custom-made door solutions including external door sets with every detail carefully tailored to specific requirements.

Next, we will look at getting the right locks for external door…